Aluminium industry

Finlands economy went down in the early 90´s,with a devaluation following. Afterwards the finnish “mark” became a fluent currency,and it led to a better situation for exportcompanies and their production.

The shipyardindustri got two big projects, Kvaerner Masa Yards to build a vessel,with aluminum-gastanks ,40 meters diameter for LNG and Finnyards to build catamarans in aluminium for Stena Line. It became a chainreaction with many jobs for subcontractors and busy times to develope smarter workingmethodes. Even todays alu-industri are benefitting from those experiences and methodes that we where a part of developing 25 years ago.

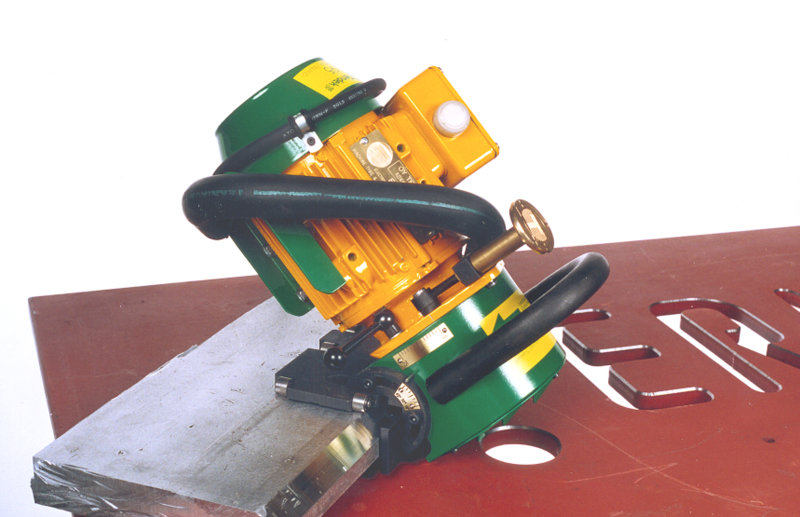

Tendek builded hand-bevelers for plates within 6-60mm thickness,as well as machines that beveled J-joints,for both sides of the plate.

Redy joints where treated. Weldingjoint and the baseplate should have the same thickness.

For this purpose Tendek built a stationairy-beveler with 2x4 kW-engines,that flat-cutted a weldingjoint to 55mm width and 6-7mm hight(to the radius midpoint).

The construction enabled cutting of in- and outside on the segments that together made the gastank.Every vessel had four of this big tanks onboard.

As well as beveling,the treatment of the joint was important in the process. The cleaness of the aluminum was essential to get perfect joints when welding.

Different sizes of cutterdiscs were put to angel-grinders.These machines are nightmares from a work-safty point of view,but since they are faster,cleaner,and superior to the grinding-tools,they became popular. But you can´t overlook the accidents that have happened,and still today is happening when using this tool.

There are no manufactorer today building angel-grinders for this purpose.And be aware of that,in many cases,there is no guarantee for durability of the machine,nor claimes can be made if accidents happens.

When using this machine,the responsability is totaly on the employer and employees.

Here are some advises that we think could come in handy:

- Before using a machine make sure you have proper education,both theoreticly and practically. Save a document that proves it, with dates and names of the participantes.

- Machines that are installed with cutters should be quality machines, but notice that even among these, there are models that doesn´t last because the weight of the cuttingdisc is heavier than the grindingdisc. Ask your salesperson about their experieces in the matter, because it might even be forbidden to sell the machine for this purpose.

- The machine should absolutely be equiped with a double-lock-system to asemble the disc, aspecially when the disc is bigger than 80mm.

- The “wheel-guard” is often used as a support when using the tool and should therfore have a “block”,so if the tencionring and bolt comes loose it prevents the “guard” to fall down on the cutterdisc.

- Use cutters made by proffessionals,as well as the sharpening of worn-out discs should be made by pros.

- The work should only be done with the protection-gear that has been agreed upon at the time of education.

- Use a “two-hand-machine” when you have to work below your waist. Such a machine should never be operated with only one hand. A “one-hand-machine” with a smaller disc we recomend for work above the waist since it´s easier to handle.

- We prefer if the tools are for individual use only. If the company is using many different kind of discs,it´s easier to avoid misstakes if you have different machines as well,and of course it makes the surrounding more secure.

- Be sure to check,both machine and cutters for maintanance,since the tencion creates more wearing. Aspecially to the pinion and gear.

- Check the sparepart-prices for a certain brand before purchase.

- The “Lever Ass´y” should be checked to avoid machine from “self-starting”.

Kokkola 25-08-2014